|

The U.S. Consumer Product Safety Commission staff and other government officials have investigated numerous complaints from homeowners throughout the nation who have had trouble with small gauge aluminum branch circuit wiring. The Commission has also had research conducted that shows that homes wired with aluminum wire manufactured before 1972 ("old technology" aluminum wire) are 55 times more likely to have one or more connections reach "Fire Hazard Conditions" than is a home wired with copper. The survey conducted by the Franklin research Institute defined “Fire Hazard Conditions” to occur when receptacle coverplate mounting screws reached 149°C (300°F), or sparks were emitted from the receptacle, or materials around the receptacle were charred.

The hazard investigated by the Commission staff occurs at connections to old technology aluminum wire, such as at outlets or switches or at major appliances such as dishwashers, furnaces, etc. Corrosion of the metals in the connection, particularly the aluminum wire itself, causes increased resistance to the flow of electric current and that resistance causes overheating.

Homes built before 1965 are unlikely to have aluminum branch circuit wiring. Homes built, rooms added, and circuits rewired or added between 1965 and 1973 may contain aluminum wiring. In 1972, manufacturers modified both aluminum wire and switches and outlets to improve the performance of aluminum wired connections. Sale of the old style wire, switches, and outlets still on dealers' shelves, however, continued after 1972.

TROUBLE SIGNS

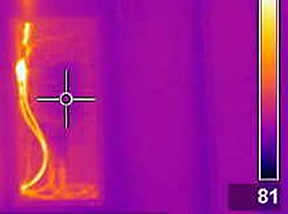

Signs of trouble in aluminum wire systems include warm-to-the-touch face plates on outlets or switches, flickering lights, circuits that don't work, or the smell of burning plastic at outlets or switches. Unfortunately, not all failing aluminum wired connections provide such easily detected warning signs; aluminum wired connections have been reported to fail without any prior indications or problems. Below are sample photos of hazardous, failed aluminum wire connections and devices.

Figure 1 Figure 2

Figure 3 Figure 4 Figure 5

Figure 6

- Figure 1 - Aluminum wire splice made with twist-on connector; connector spring is red hot.

- Figure 2 - These two failed, charred splices have overheated, melted, and adhered together.

- Figure 3 - Severe charring of this plastic shell indicates that it has probably ignited.

- Figure 4 - Wire failure on top of hot water tank caused by faulty twist-on connection.

- Figure 5 - Charred receptacle body and disintegration of the wire insulation behind visable area.

- Figure 6 - Infrared photo of an overheated wire behind a wall between studs.

WHAT THE HOMEOWNER CAN DO

If you have noticed any of the trouble signs, have a qualified electrician determine whether the problem is caused by deteriorating connections to aluminum wiring. DO NOT TRY TO DO IT YOURSELF! You could be electrocuted or you could make the connections worse by disturbing them. If you are not certain whether your home has aluminum branch circuit wiring, you may be able to tell by looking at the markings on the surface of the electric cables which are visible in unfinished basements, attics, or garages. Aluminum wiring will have "Al" or "Aluminum" marked every few feet along the length of the cable. (Note - the marking "CU-clad" or "Copper-clad" in addition to the "Al" or "Aluminum" means that the cable uses copper-coated aluminum wire and is not covered in this article.)

If you do have aluminum branch circuit wiring, the Commission suggests that you have a qualified electrician check the system for impending trouble. Remember, you may not have noticed any of the warning signs, but research shows that trouble may develop over time and an electrician may spot potential problems before you notice them.

If your electrician determines that you need to expand your current use to add on devices with copper wire, an AlumiConn Aluminum-to-Copper connectors may be used to pigtail copper conductors onto existing aluminum wire. AlumiConn is UL listed as of May 21, 2007 and has been independently tested. This independent test was conducted by aluminum wire expert Dr. Jesse Aronstein. The test report is a very important read if your home has any aluminum wire. (AlumiConn information is found on page 9 of the report.) It is generally not necessary to rewire your whole house or to use other more expensive solutions. AlumiConn is an effective, economical, complete, and permanent aluminum wiring repair solution. To read more about aluminum wiring or the AluminConn Aluminum-toCopper Connector, please visit their website at http://www.alcopstore.com/. If your electrician determines that you need to expand your current use to add on devices with copper wire, an AlumiConn Aluminum-to-Copper connectors may be used to pigtail copper conductors onto existing aluminum wire. AlumiConn is UL listed as of May 21, 2007 and has been independently tested. This independent test was conducted by aluminum wire expert Dr. Jesse Aronstein. The test report is a very important read if your home has any aluminum wire. (AlumiConn information is found on page 9 of the report.) It is generally not necessary to rewire your whole house or to use other more expensive solutions. AlumiConn is an effective, economical, complete, and permanent aluminum wiring repair solution. To read more about aluminum wiring or the AluminConn Aluminum-toCopper Connector, please visit their website at http://www.alcopstore.com/.

< Back to Safety Alerts and Recalls |