Many homes built in the last 20 years or so have PEX tubing as a part of the plumbing system, and it can also be found in the revamped plumbing systems of older homes. PEX is made from crosslinked High Density Polyethylene (HDPE) polymer and looks similar to a garden hose when coiled up. Crosslinking is a chemical reaction that allows HDPE to become stronger, more flexible, and more resistant to cracking due to cold temperatures or upon impact. PEX has several advantages over copper pipe and rigid plastic pipe such as PVC. It is flexible, resistant to scale and chlorine, doesn't corrode or develop pinholes, is faster to install, and has fewer connections and fittings. Many homes built in the last 20 years or so have PEX tubing as a part of the plumbing system, and it can also be found in the revamped plumbing systems of older homes. PEX is made from crosslinked High Density Polyethylene (HDPE) polymer and looks similar to a garden hose when coiled up. Crosslinking is a chemical reaction that allows HDPE to become stronger, more flexible, and more resistant to cracking due to cold temperatures or upon impact. PEX has several advantages over copper pipe and rigid plastic pipe such as PVC. It is flexible, resistant to scale and chlorine, doesn't corrode or develop pinholes, is faster to install, and has fewer connections and fittings.

The difficulty occurs when brass fittings and valves are used with PEX. Brass is a copper alloy that may contain between 5 to 40% zinc. Zinc is added to brass to increase tensile (tension) strength. Since the corrosion of brass increases as the percentage of zinc increases, it is generally recommended that the percentage of zinc in brass fittings be less than 15% although some experts say that number can safely go to 19%. The dilemma is that many brass fittings and valves on the market have a zinc content of 35% or more. Zinc is a highly reactive metal and it has a weak ability to bond to other metals at the atomic level. When water flows through the fittings and valves it corrodes the metal; zinc leaches from brass and creates a powdery buildup inside the fittings. This corrosion process is known as dezincification, and it causes two main problems. First, the zinc builds up inside the walls of the fitting which decreases water flow and eventually causes a blockage. Second, the porous copper-rich structure that is left behind has little mechanical strength and is prone to seepage and breakage.

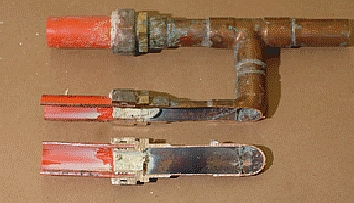

New Brass Fitting Corroded Brass Fitting

What are some telltale signs that dezincification is taking place? There may be a powdery white substance (zinc oxide) and/or mineral stains on the exterior surface of the brass fitting or valve. Water may also be weeping from the fitting body or the seal. When the situation is acute, there can be signs of water damage in the floors, ceilings, and walls surrounding the faulty plumbing.

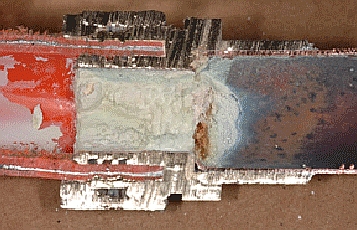

Cross section of dezincified fitting Close-up of a dezincified fitting

Water damage cause by leaking dezincified fitting/valve behind wall

These are some of the service conditions which have been present where dezincification has occured:

-

Water containing high levels of chlorine, chloride ion, oxygen and carbon dioxide

-

Water high in mineral content, otherwise known as "hard water"

-

Stagnant or slow moving waters

-

Slightly acidic water that is low in salt content and at room temperature

-

Neutral or alkaline water that is high in salt content and at or above room temperature

Although there are a number brands of brass fittings and valves on the market today that are susceptible to dezincification, our list of offenders is by no means intended to be complete. However, according to ASHI®, and in the light of various class-action lawsuits, some of the culprits have been Zurn PEX, Kitec, Rehau, Wirsbo, and Vanguard. Although some companies sell "dezincification-resistant" brass fittings, check with the manufacturer that the percentage of zinc is less than 15% before installing them in your home.

Your plumbing is only as good as the products used. Unfortunately if you have failure-prone brass fittings and valves in your home, you may have a ticking time-bome behind your walls. If you discover flexible plumbing lines in your home and you are not sure if your situation merits concern, contact a licensed, professional contractor/plumber trained to recognize the presence of dezincification. Additionally, you may contact an ASHI® certified home inspector to evaluate the situation.

<< Back to Technical Library |